Key Factors For Choosing Safe and Reliable Wire & Cable

Mar 24,2021

Mar 24,2021

Red Banner Electrician

Red Banner Electrician

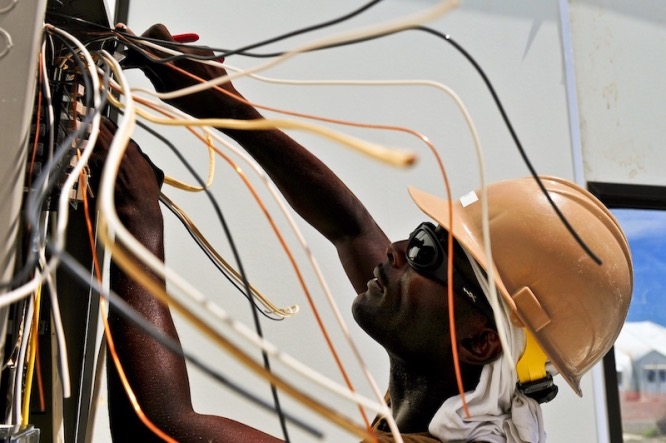

Wire and cable are important products that are closely related to everyone. They directly affect our safety, including our lives and property. Using inferior wires and cables can easily cause accidents such as fire and electric shock. So, what kind of wire and cable is safe, and how to choose?

Manufacturers who produce wires and cables must have the necessary product certificates and quality inspection reports. Consumers should pay attention to the purchase of products from regular manufacturers, and ask for the relevant product certification documents. In addition, pay attention to the relevant instructions when using wires and cables.

Qualified wires and cables have certain requirements in terms of packaging, appearance, resistance, structure, and materials. High-quality cables provide us with higher security, while the use of poor-quality cables can easily cause dangers such as leakage, electric shock, and fire, and bring hidden dangers to the normal operation of the power system.

1. Observe the packaging

Under normal circumstances, wires and cables are packaged in rolls of 100 meters per circle, and the coiled wires should be tightly wrapped with transparent film, and the certificate of conformity should be tightly wrapped in the film. The cable packaging produced by regular manufacturers should be marked with:

(1) Factory Name and Trademark

(2) Product Model and Specifications

(3) Product standard code

(4) Manufacturing date

2. Judging from the appearance of the product

Makesure the appearance of the product is smooth and round, and the color is uniform. Wire and cable companies whose products meet the requirements of national and international standards will strictly control the purchase of raw materials, production equipment, and production processes in order to improve product quality and ensure that products meet standard requirements.

Therefore, the appearance of the produced wire and cable products meets the standard requirements, smooth and round, and uniform in color, while fake and inferior products often have a rough and dull appearance. For rubber insulated flexible cables, the appearance is required to be round, and the sheath, insulation, and conductors are tight and not easy to peel off. However, fake and inferior products have a rough appearance, large ovality, and low insulation strength of the sheath, which can often be torn apart by hand.

Avoid buying cables whose insulation and jacket are made from recycled waste. Cables made of recycled waste materials have poor tensile strength and elongation, short service life, and are prone to insulation breakdown when subjected to high-temperature power transmission for a long time. This could expose live conductors and cause short circuits, spontaneous combustion, and other hazards.

3.To choose a cable with qualified resistance

Resistance is an important reference index for whether the conductor material and interface of the wire and cable meet the regulations. In order to reduce costs, some companies in the market may reduce copper materials, which account for 80% of raw material costs, by using impure recycled copper or reducing the cross-sectional area of conductors. This will lead to excessive resistance of the conductor, accelerate the aging of the insulation layer, and easily cause a fire during use. Therefore, it is very important to choose a cable with qualified resistance.

In addition, it is also important to select cables with qualified sheath thickness, insulation thickness, eccentricity and structural dimensions. When the thickness of the sheath and insulation does not meet the standards, it will reduce the compressive strength of the wire and cable, resulting in shortened service life, and even breakdown, short circuit, and fire.

To sum up, the sheath material, thickness, structural size of the cable, as well as the material of the conductor and whether the material is sufficient are all important criteria that affect our selection of cables. We must choose qualified wires and cables so as not to pose a threat to our lives and properties.

Unqualified wires and cables not only affect our use, but also directly affect our life safety, so we must choose cables with excellent quality. Qualified manufacturers use brands to guarantee product quality.

Shenzhen RedBanner Electric Technology Co., Ltd. always selects high-quality raw materials. As a professional cable manufacturer with 18 years of industry experience, we have become one of China's most respected cable manufacturers.

As a manufacturer of high-end industrial weak current cables, we adhere to a strict quality control system. The quality of the company's products is guaranteed, and the environmentally friendly wires meet modern fire safety requirements.

Our products have been used in many government projects, including the stage of China Central Satellite TV's Spring Festival Gala, the Guangdong Hong Kong-Zhuhai-Macao Bridge, the Guangzhou University City, and the Shenzhen Metro.

Shenzhen Red Banner Electric Technology Co., Ltd. produces high-quality and high-value cables, allowing you to buy with confidence.

HOME

HOME We are honored to announce that we have ISO 9001:2015 certification.

We are honored to announce that we have ISO 9001:2015 certification.  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address