Flexible Cable Guide: PVC vs. PUR vs. TPE Jacket Materials

Apr 12,2023

Apr 12,2023

Red Banner Electrician

Red Banner Electrician

Choosing the Right Jacket Material for Flexible Cables: PVC, PUR, or TPE?

Introduction:

In the ever-evolving world of electronics and machinery, the choice of flexible cable materials has never been more pivotal. The quality, longevity, and performance of a flexible cable can significantly depend on its jacket material. With the market offering materials like PVC, PUR, and TPE, understanding the nuances of each becomes crucial. This article delves deep into the considerations for selecting between these materials and how they influence cable performance and lifespan.

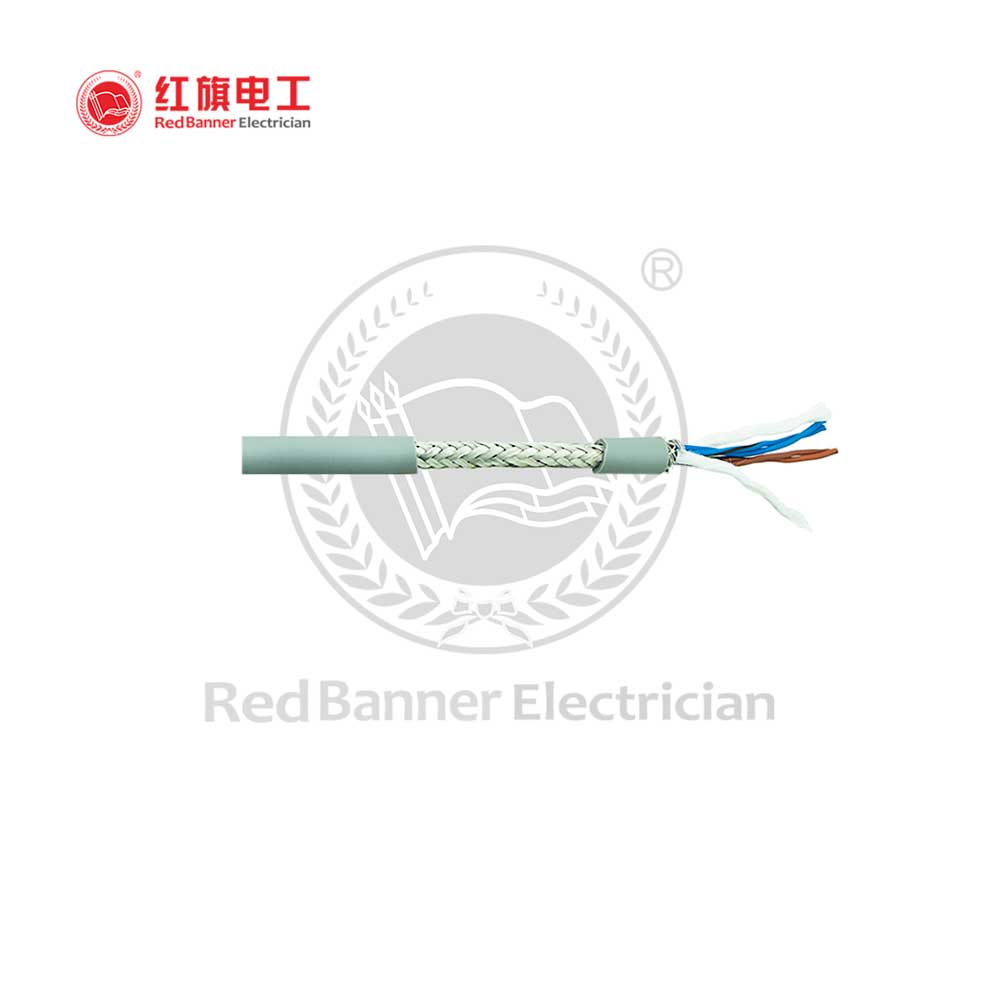

1. The Problem: Understanding Jacket Materials for Flexible Cables

The jacket of a flexible cable plays a dual role - protecting the inner conductors from external elements and influencing the cable's flexibility. Each material - PVC, PUR, and TPE - comes with its unique set of properties. For instance, while PVC is known for its durability and cost-effectiveness, PUR offers excellent resistance against abrasions. TPE, on the other hand, stands out for its flexibility and resilience. The challenge lies in determining which material aligns best with the specific requirements of an application.

2. The Importance: Why Your Choice of Jacket Material Matters

The longevity and performance of a flexible cable are intrinsically linked to its jacket material. A wrongly chosen material can lead to frequent cable replacements, interrupted operations, and increased costs. For instance, in environments where the cable is subject to constant movement, a TPE jacket might outperform PVC. Similarly, in abrasive conditions, a PUR jacket could offer better protection, ensuring the cable's longevity. Hence, understanding the strengths and limitations of each material is paramount.

3. Suggestions: Making an Informed Decision

When choosing between PVC, PUR, and TPE for flexible cables:

- Evaluate the Environment: Consider factors like temperature extremes, exposure to chemicals, and the level of abrasion the cable will face.

- Determine the Application: For static applications, PVC might suffice. For dynamic applications with constant movements, TPE or PUR could be more suitable.

- Budget Considerations: While TPE and PUR might offer advanced features, PVC is often more budget-friendly.

By weighing these factors, one can make a choice that ensures optimal cable performance and longevity.

Summary:

The choice of jacket material for flexible cables, be it PVC, PUR, or TPE, plays a pivotal role in determining the cable's performance and lifespan. By understanding the unique properties of each material and evaluating the specific requirements of an application, one can make an informed decision that guarantees both quality and cost-effectiveness.

HOME

HOME How Temperature Resistance Varies Among Flexible Cable Products

How Temperature Resistance Varies Among Flexible Cable Products  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address